How Many Cycles Does A Bedpan Washer Disinfector Have And What Do They Do?

A washer disinfector does far more than just ‘wash’ your reusable bedpans. A careful process of rinsing, disinfecting and drying will make sure that your utensils are sanitised – but what does this mean, exactly?

In order to keep your patients and residents safe from healthcare-acquired infections (HCAIs), you must have a scrupulous approach to infection control, with carefully managed processes to cover each point of risk.

Human waste is a well-known carrier of HCAIs such a clostridium difficile and MRSA. Where toileting aids such as bedpans and urinals must be reused, it’s critical that the bacteria which causes these infections is denatured – which is exactly what a washer disinfector is designed to do, using a series of three cycles in every processed load.

1. Cleaning

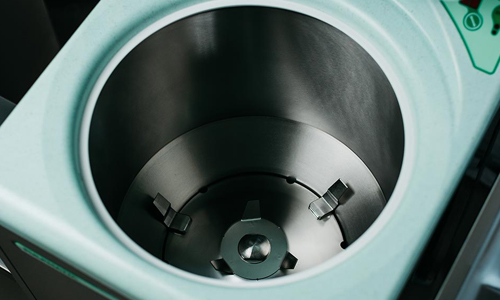

When an item is first placed in a washer disinfector and the process begins, it will be flushed with water to remove the bulk of the waste.

No detergent is used at this stage. The amount, and force, of the water from the wash array will be what removes the soil from the surface of the utensils; but it won’t sanitise them at this stage.

2. Disinfection

The disinfection stage is arguably the most critical – it’s the process which kills the bacteria which could potentially make your patients and caregivers unwell.

In this process, thermal disinfection is achieved by generating steam and which maintains moist heat on utensil surfaces. The bedpan washer disinfector chamber is then held at a specific temperature, for a pre-set length of time, to guarantee that dangerous pathogens will be destroyed. This is known as ‘thermal disinfection’.

3. Drying

Drying utensils after disinfection is an essential part of the cycle. Where items are hot after thermal disinfection, flash evaporation of residual moisture will ensure that your bedpans are ready to use or store as soon as the cycle ends.

Cycle Variables

When purchasing a washer disinfector, you should think about the potential differences between models; this will often be a series of physical variables, which impact the cycle of the machine.

Key variables to consider are:

- Time

- Temperature

- Water Volume

- Flow Rate

- Detergent concentration

These elements will influence the efficacy of a washer disinfector’s cleaning and sanitation processes, so it’s important to compare and contrast before making a purchase.

Considering Cycle Times

Cycle times should be a deciding factor in which washer disinfector you purchase.

The loading capacity and overall size of the unit will let you know how many utensils can be treated in a single cycle, but overall throughput is also affected by cycle times and availability; whether you can access a machine in the right place, as well as the right time.

To accommodate for this, you should ensure that the cycle time of the machine, as well as its capacity, are in line with your expectations – as well as the number of machines you need to purchase. In addition, cycle times can also be adversely affected by inadequate services, such as low water pressure and temperature – so be sure to verify the conditions of your own estate, too.

If you’re not sure which washer disinfector to choose, DDC Dolphin can ensure that you find the exact model to suit your requirements. We can not only assist with the purchasing stage, but sluice room design, planning and maintenance, too.

Contact us today to find out more